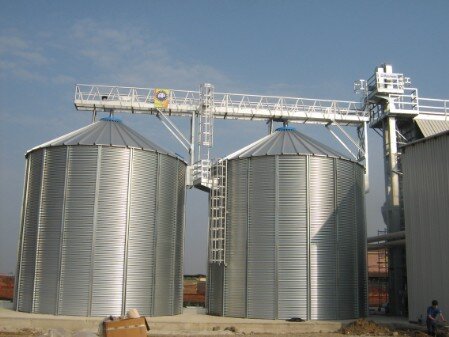

Storage silos

The silo made by AP for grain storage reliably protects its loaded contents from various weather influences and other spoilage. Such as from birds and rodents.The metal tank is equipped with a roof and bottom, as well as special channels for ventilation of the storage product.Officine Pomatto equips its tanks with various layer-by-layer temperature control systems for the stored crops and active ventilation. The ventilation system controls the air flow.The metal grain silo not only allows for the accumulation and storage of wet grain through ventilation and cooling of the product, but also ensures minimal expenses and losses during this process.Ladders, upper and lower doors are used for more convenient and easier maintenance, repair and cleaning of grain storage silo equipment and structures.

Performance and sturdiness: AP grain silos

GRAIN SILO DESIGN

METAL GRAIN SILO ROOF

The silo roof is a complex structure consisting of trapezoid-shaped sectors, bolted together by gaskets and stiffeners. The height of the stiffeners is up to 200 mm. The roof sectors are made of galvanised steel.Depending on the diameter, agricultural silos can be equipped with a one-tier, two-tier and three-tier roof. This allows the roof to withstand significant snow loads.On the roof of a grain storage silo, a loading device, an inspection hatch, a service ladder and a series of devices for the thermal suspension of the layer-by-layer temperature control system for the grain mass are installed. There are also air ducts on the roof, which are sometimes equipped with special fans.

CEREAL SILO SHELL

The grain storage silo shell is shaped like a cylinder and is made of galvanised steel panels with a corrugated profile. Galvanised steel serves as the main material from which all the panels of the agricultural silo shell are made. The thickness of the zinc coating varies from 18 to 40 microns.The grain bin shell is reinforced with vertical stiffeners, which are installed on the outside. Often, two stiffeners are used on each panel, but in some grain bin models, to increase the strength on one panel, the stiffeners are mounted in three rows.To form a reliable and durable joint, the vertically positioned stiffeners are fixed with overlaps of identical shape to the ribs themselves or using special plates.

CONES SILOED FUNDS FOR SHORT-TERM STORAGE

The conical bottoms of the metal grain silo are mounted by trapezoidal steel sectors. The angle of the bottom is 45°, 55° or 65°, thus creating optimal conditions for gravity discharge of the stored grain product. The sectors on bolted connections with special seals are fixed.In the lower part of the conical bottom of the grain storage silo, there is an unloading device in the form of a rack and pinion valve.At the top, the bottom cone is attached to the main support ring. This ring transfers the load from the weight of the metal structures and the weight of the stored grain to the vertical supports of the silo, based on a concrete foundation slab. By properly calculating the height of the supports, the grain is discharged from the silo by gravity to the conveyors, which are installed below the valve, at foundation level.

ACTIVE VENTILATION SYSTEM FOR GRAIN SILO

The active ventilation system of an agricultural silo comprises air channels and one or more ventilators. Long-term grain storage silos are equipped with a lower ventilation system. It is placed in the concrete basement and covered by special perforated structures.In addition, to create active ventilation, roof and wall ducts are installed. In addition, roof and wall ducts are fitted to create active ventilation.The supply of air at various temperatures (chilled, heated or room temperature) is used for ripening, cooling or cold storage of the grain during storage.

FIXING

In the assembly of metal-grained silos, bolts and nuts with a special protective zinc coating are used. The bolts for connecting the roof and bottom sections as well as the silo body panels are equipped with polymer seals and special conical washers.Around the perimeter of the silo in the vertical and horizontal joints, a special sealant made of material approved for use with foodstuffs is used.The use of bolted joints provides fast and reliable assembly of metal structures at minimal cost and without damage to the corrosion-resistant coating.